Electroplating is a common metal surface treatment solution. Electroplating can not only increase the appearance of the product, but also improve the performance of the product. Therefore, after the hardware electroplating process, it is necessary to test whether the electroplating is qualified according to strict testing standards. Specifically, it can be analyzed from the following aspects:

1. Plating thickness: This is one of the basic items of electroplating detection, which is directly related to the service life and production cost of the product. Common detection methods include visual inspection, measurement tool measurement and X-ray thickness gauge. X-ray thickness gauge has the advantages of high precision and high efficiency, and is suitable for electroplated products with complex shapes.

2. Plating bonding strength: refers to the bonding strength between the coating and the base material, which is one of the important indicators of electroplating quality. Detection methods include tensile test, peeling test, etc., through which the impact resistance, wear resistance and corrosion resistance of the coating can be determined.

3. Plating uniformity: refers to the distribution of the coating on the surface of the product, which is one of the important indicators of the appearance inspection of electroplated products. Detection methods include visual inspection, metallographic microscope inspection, etc.

4. Plating solution composition analysis: It is essential to analyze and detect the composition of the plating solution. Commonly used detection methods include spectral analysis, chromatograph-mass spectrometry, ion concentration determination, etc. Spectral analysis can accurately determine the content of various metal elements in the plating solution.

5. Mechanical and physical properties test: including test items such as coating thickness, potential difference, micropore density, peeling test, sawtooth test, gravel impact, coating ductility, etc., used to evaluate the mechanical and physical properties of electroplated products.

6. Chemical resistance test: test items such as sweat and water resistance test, anti-fouling and cleanability, solvent resistance, etc., used to evaluate the chemical stability of electroplated products.

7. Environmental resistance test: including high temperature test, low temperature test, constant temperature and humidity test, etc., used to evaluate the performance of electroplated products under various environmental conditions.

These test items and methods together constitute a comprehensive system of electroplating testing to ensure that the quality of electroplated products meets standards and customer requirements.

Related news

-

Key points of electroplating of pogo pin parts in precision electronic connector electroplating

Pogopin is a common electronic connector. Due to its size and precision, it is generally processed by roll plating. The following is the key points of electroplating from the three parts of pogopin: spring, barrel and plunger: -

Advantages and disadvantages of common electroplating layers in medical microneedle electroplating

Due to the wide application and particularity of medical microneedles, the electroplating layer of medical microneedles plays an important role in their application. The following introduces the common electroplating layers of medical microneedle electroplating processing. -

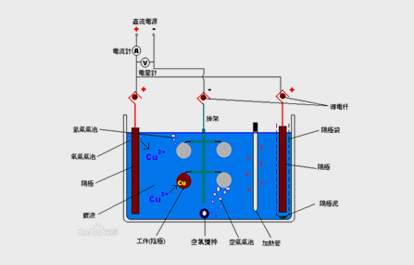

Plating Principles and Classification

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. It is a process of using electrolysis to attach a layer of metal film to the surface of metal or other material parts to prevent metal oxidation ( Such as rust), improve wear resistance, conductivity, reflectivity, corrosion resistance and... -

Environmental nickel free plating manufacturer - copper tin zinc plating

One in every 1 million people in the world is allergic to metals. The most common allergen metal is nickel. Once allergies occur, it can cause contact dermatitis manifestations such as redness, itching, and yellow water around the contact. These are all adverse reactions caused by the release of metal ions. Once metal allergic dermatitis occurs, the most fundamental and effective treatment The solution is to isolate the allergen. -

Wastewater Treatment at HYP

Electroplating enterprises and surface treatment enterprises have chemical oxidation, anodic oxidation, galvanizing, zinc-nickel alloy plating, chrome plating, copper plating, gold plating, nickel plating, silver plating and other plating types, and the wastewater produced is very messy.