Quality Management System

Laboratory

1. Analysis and inspection of raw material’s and product’s quality.

2. Control and inspection during production.

3. Provide analysis and testing for technological transformation and new product development tests.

Testing Area

Solution preparation and chemical analysis solution concentration, proportion, Baume degree, etc.

AAS Atomic Absorption Spectrophotometer

Function: Determination of gold, palladium, platinum and other metal content in the plating solution.

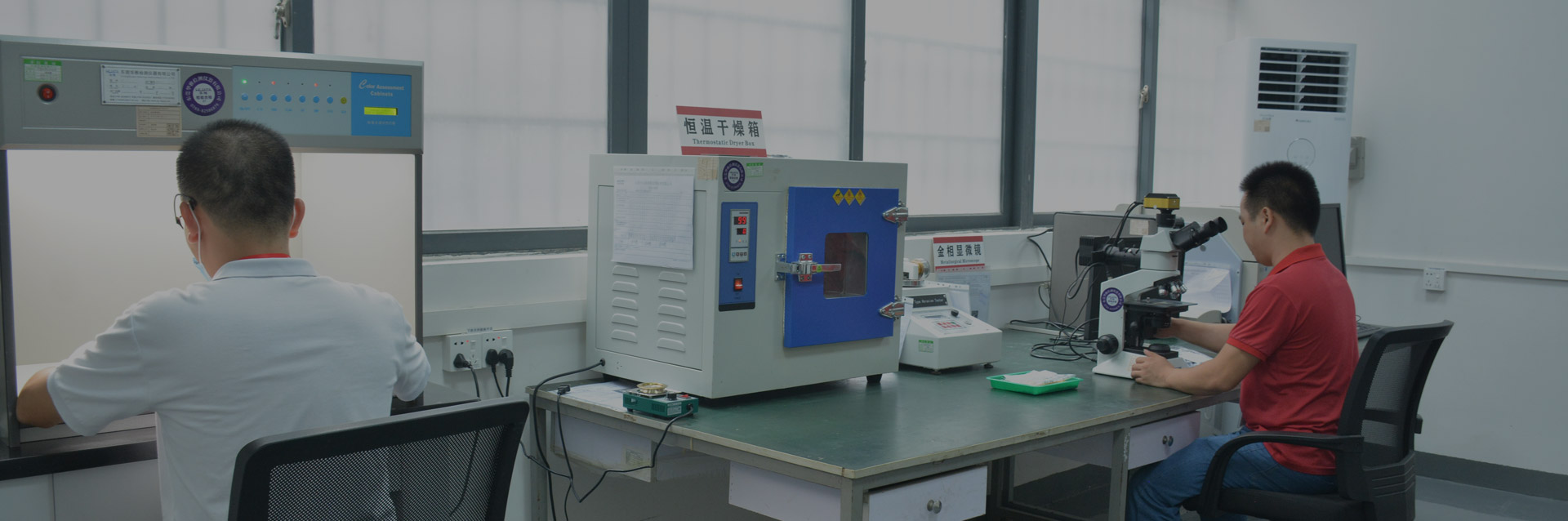

Reliability Lab

HYP's environmental reliability test is an activity to evaluate the functional reliability of the product in all environments such as expected use, transportation or storage during the specified life span. In addition, environmental tests can be used to analyze and verify the degree of influence and mechanism of various environmental factors on product performance.

X-Ray Coating Thickness Gauge

Function: To detect the coating thickness of the product.

Salt Spray Test Machine

Function: Simulate salt spray environmental conditions to test the corrosion resistance of product surfaces.

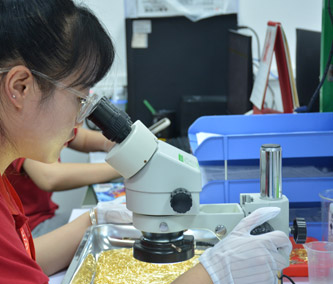

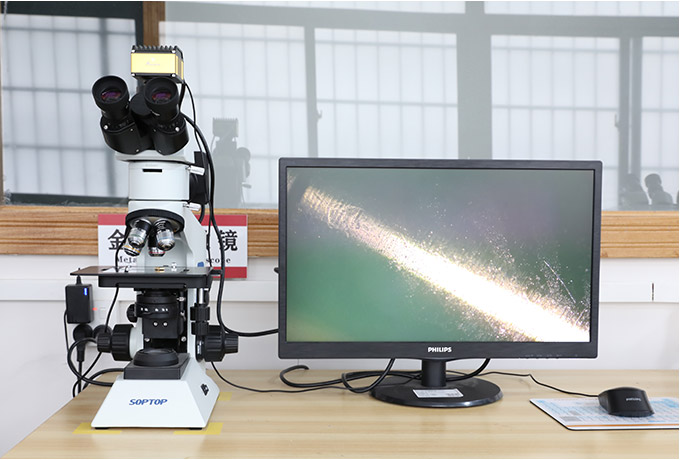

Metallurgical Microscopes

Function: Able to detect particles on coating surfaces, observe attached foreign matter and the composition of the coating on a sample cross section. Provides image measurement capabilities.

Programmable Constant Temperature & Humidity Test Box

Function: Allows products to be tested in various temperature and humidity conditions.

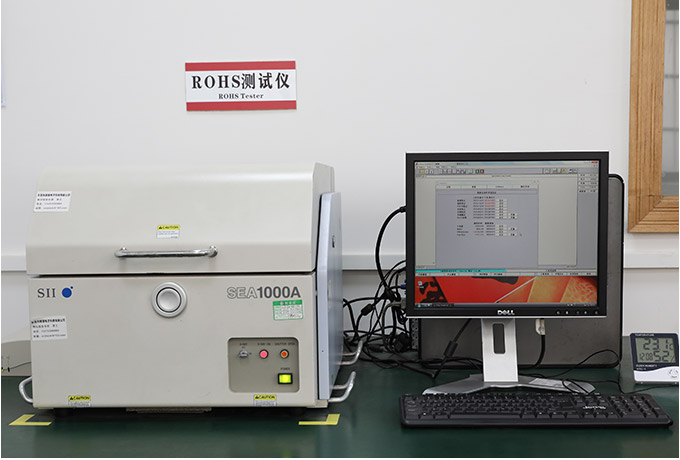

ROHS Tester

Function: Tests for six harmful substances including lead Pb, cadmium Cd, mercury Hg, hexavalent chromium Cr6+, polybrominated diphenyl ether PBDE, and polybrominated biphenyl PBB.

JEOL Scanning Electron Microscope

Function: Able to test coating thickness and provide element analysis.

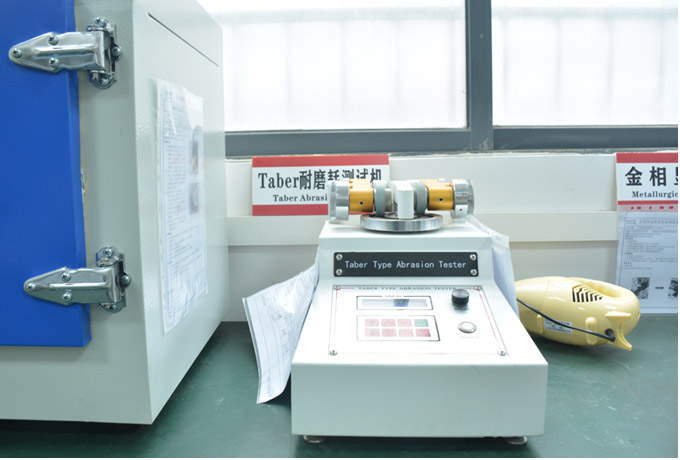

Taber Abrasion Tester

Role: Used to check the wear resistance of the coating.

Standard Light Source for Color Light Box

Function: Provides an ability to observe the appearance color of the product surface by using different light sources.