Industry: Electric Toothbrush Industry solution

Problem: Waterproof and corrosion resistance problem

The electric toothbrush uses a high-speed vibration movement to drive the brush head to rotate or vibrate to achieve the effect of cleaning teeth. As an electronic product, but daily use requires contact with water, so waterproof performance is a very important aspect of electric toothbrush. HYP uses a special coating when electroplating the Pogo pins to improve the waterproof performance and corrosion resistance of the components.

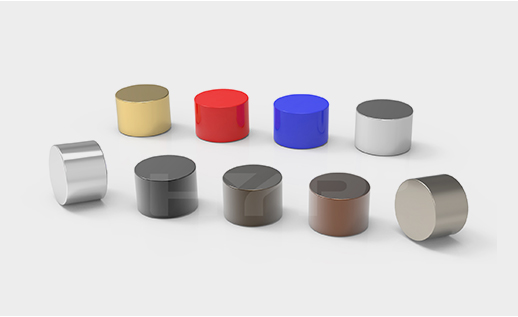

Applications:Electric toothbrush electroplating application scheme

CFE-S37 Plating Formula:Ni+PdNi+Others

Test method:Place the positive and negative electrodes in the specified household water , observe and feedback the corrosion situation under a microscope at 40 times after power on.

Requirement: Conductivity>100uS/cm;

Performance conclusion:Domestic water (continuous)>4H

CFE-S37 Plating Formula:Ni+PdNi+Others

Test method:Place the positive and negative electrodes in the specified household water , observe and feedback the corrosion situation under a microscope at 40 times after power on.

Requirement: Conductivity>100uS/cm;

Performance conclusion:Domestic water (continuous)>4H