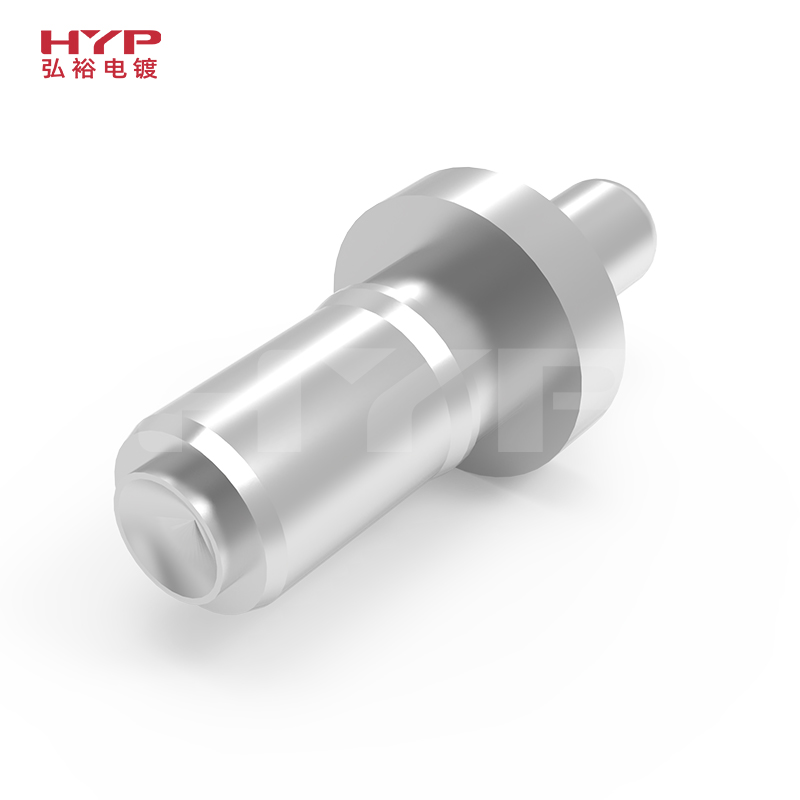

Industry: The smart wear industry includes intelligent watches, intelligent lasses, AR, etc

Problem: Corrosion and electrolysis resistance

Smart wearable device is a general term for wearable devices designed and developed with intelligent technology for daily wear, such as watches, bracelets, glasses, clothing, etc. The advent of the era of wearable intelligent devices means the extension of human intelligence. Through these devices, people can better perceive external and self-information, process information more efficiently with the assistance of computers, networks and even others, and achieve more seamless communication.

The corrosion of metal material surfaces by salt spray is caused by the penetration of chloride ions through the oxide layer and protective layer on the metal surface and the electrochemical reaction with the internal metal. Salt spray corrosion can destroy the metal's protective layer, causing it to lose its decorative effect and reduce its mechanical strength.

General household electronic products only need to be resistant to salt spray corrosion for 48 hours, but wearable devices are different. Because the product comes into contact with the human body, the human body will secrete sweat, and sweat corrosion is a much more rigorous form of corrosion than salt spray corrosion, so the parts of wearable device products need stronger corrosion resistance.

Through research on electrolytic corrosion, HYP has found that some special elements and electroplating methods have particularly good corrosion resistance effects. Our salt spray tests can range from 48 hours to 400 hours, sweat tests from 48 hours to 500 hours, and the most stringent electrolytic tests can also reach 120 minutes, which can meet all the requirements of major customers in the market.

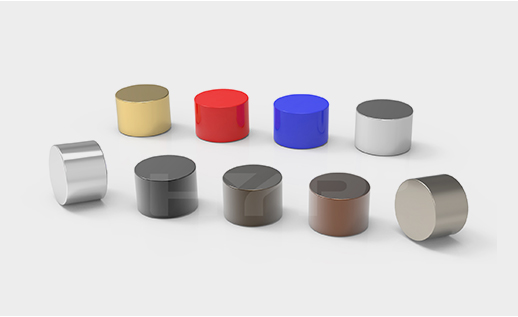

CFE-S51 Composite Plating:Cu+Au+Others

Test solution: ISO 3160, Pickering Sweat

Test method:Place the positive and negative electrodes into ISO3160 and Pickering sweat, observe the corrosion situation under a 40X microscope after applying an electric current and provide feedback.

Requirement:No visible damage to the appearance;

Performance conclusion: ISO3160-2 Sweat >4H, Pickering Sweat >50Min