Pogopin is a common electronic connector. Due to its size and precision, it is generally processed by roll plating. The following is the key points of electroplating from the three parts of pogopin: spring, barrel and plunger:

1. Spring:

Springs are usually made of beryllium copper, stainless steel and steel wire. Each material has its own unique characteristics. In the electroplating design of springs, it is necessary to consider the operating temperature, impedance and elasticity requirements. Springs are usually treated with roll silver plating or roll gold plating. Silver plating obtains good conductivity and high thermal performance, and gold plating prevents oxidation and corrosion.

2. Barrel:

The pogo pin barrel is a turned part, generally brass gold plating or stainless steel gold plating, nickel plating and then electroplating gold. Nickel plating is a general surface treatment layer, and its thickness is basically 0.1 to 1.0μm. When electroplating blind hole tubes with small diameters and long diameters, side holes are usually opened at the bottom to allow the electroplating solution to fully reflux at the bottom of the tube to ensure that the inner wall of the inner tube is precipitated into the gold component. There are other electroplating layers such as rhodium ruthenium plating, palladium plating, platinum plating, and other composite plating layers.

3. Plunger:

The method of electroplating the pin shaft is similar to that of the barrel. Basically, roll gold plating is preferred because gold has excellent conductivity and oxidation resistance. The thickness of the electroplated gold will also affect the life of the entire pogo pin connector.

The above points about pogo pin electroplating in electronic connectors are shared here. For more precision electroplating and roll plating solutions, please consult Dongguan HYP Electroplating.

Related news

-

Common items and methods for precision metal plating testing

Electroplatingisacommonmetalsurfacetreatmentsolution.Electroplatingcannotonlyincreasetheappearanceoftheproduct,butalsoimprovethepe... -

Advantages and disadvantages of common electroplating layers in medical microneedle electroplating

Due to the wide application and particularity of medical microneedles, the electroplating layer of medical microneedles plays an important role in their application. The following introduces the common electroplating layers of medical microneedle electroplating processing. -

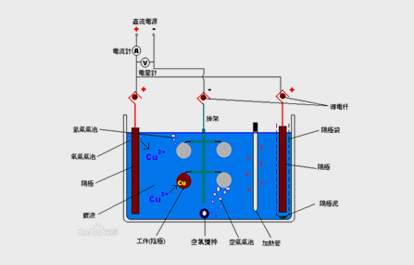

Plating Principles and Classification

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. It is a process of using electrolysis to attach a layer of metal film to the surface of metal or other material parts to prevent metal oxidation ( Such as rust), improve wear resistance, conductivity, reflectivity, corrosion resistance and... -

Environmental nickel free plating manufacturer - copper tin zinc plating

One in every 1 million people in the world is allergic to metals. The most common allergen metal is nickel. Once allergies occur, it can cause contact dermatitis manifestations such as redness, itching, and yellow water around the contact. These are all adverse reactions caused by the release of metal ions. Once metal allergic dermatitis occurs, the most fundamental and effective treatment The solution is to isolate the allergen. -

Wastewater Treatment at HYP

Electroplating enterprises and surface treatment enterprises have chemical oxidation, anodic oxidation, galvanizing, zinc-nickel alloy plating, chrome plating, copper plating, gold plating, nickel plating, silver plating and other plating types, and the wastewater produced is very messy.